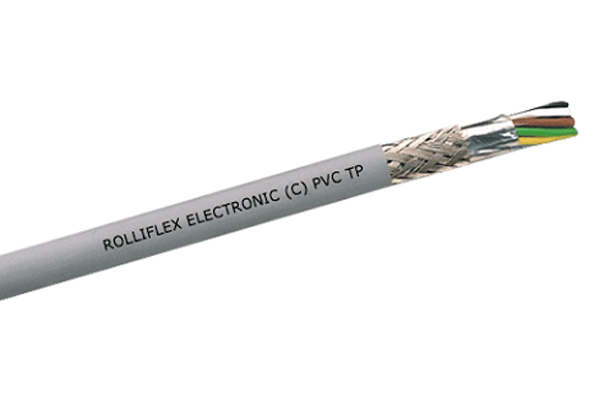

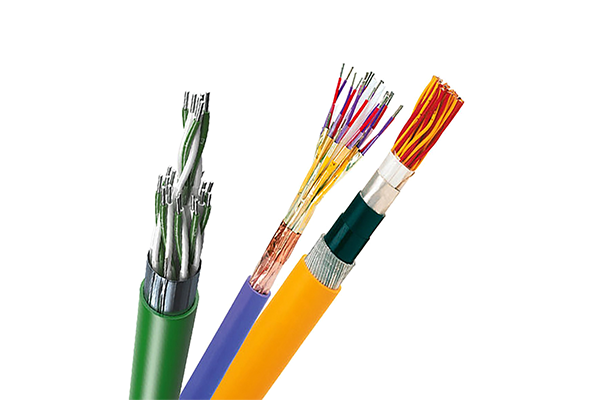

Instrumentation & Control Cables Manufactured

to BS:5308/IS:1554/EN:50228 Standards

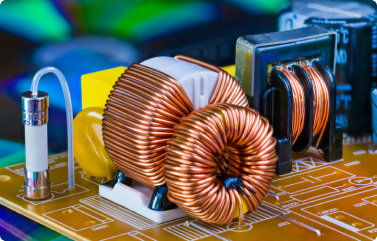

Rolliflex Thermocouple Extension and Compensating Cables are meticulously crafted to maintain guaranteed identification characteristics in accordance with their respective thermocouples, even within restricted temperature spans. These cables facilitate the extension of temperature sensors to a stable position, allowing the effective cold junction to be relocated to the remote end of the extension or compensating cable. This capability is essential for accurate temperature monitoring in diverse industrial environments, including manufacturing, chemical processing, and power generation.

To ensure exceptional quality, each batch of our cables undergoes rigorous testing for Thermo-EMF performance and electrical and mechanical properties. These tests comply with the internationally recognized ANSI MC 96.1 standard, providing customers with the assurance that they are receiving cables that perform reliably and consistently. Additionally, our dedicated research and development team is committed to addressing special customer requirements, enabling us to tailor our products to meet specific application needs.

Tap for enquiry