Why Power Factor Correction

Matters

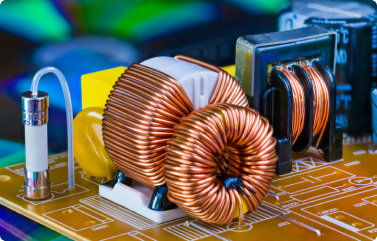

Power factor correction optimizes the

efficiency of electrical systems by minimizing reactive power, reducing energy losses, and

lowering electricity costs. However, achieving a near-unity power factor with conventional

contactor-based systems is challenging, particularly for fast-switching loads. Issues such as

arcing, high inrush currents, and delayed response times make traditional methods less effective

for modern industrial applications.

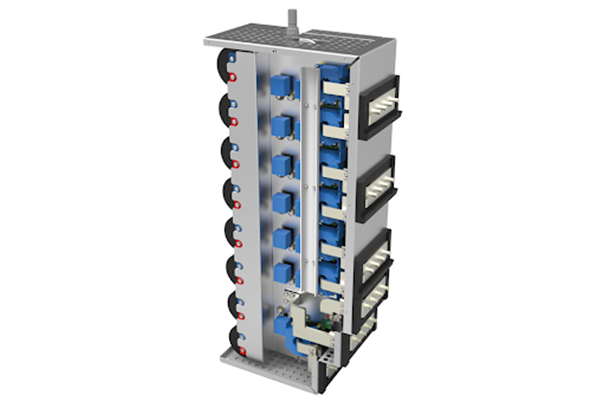

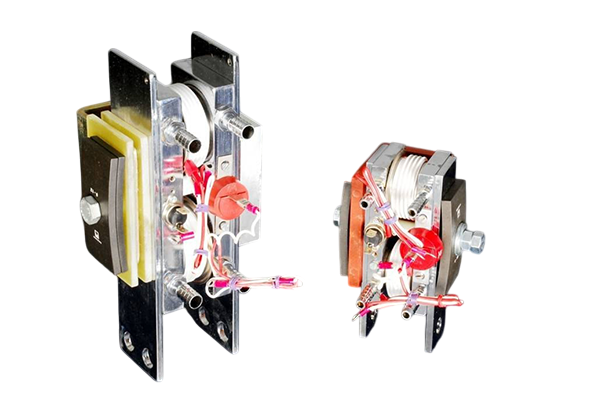

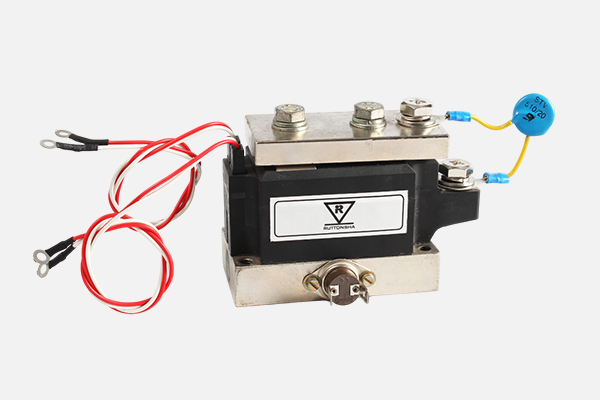

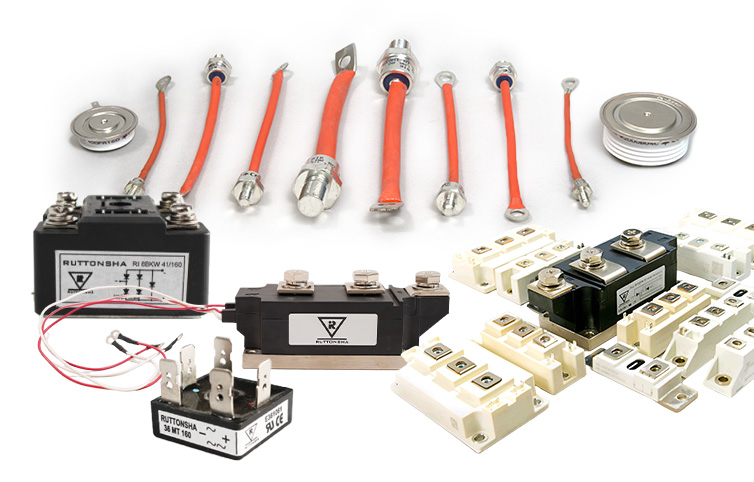

The Revolution: Thyristor

Switch Modules

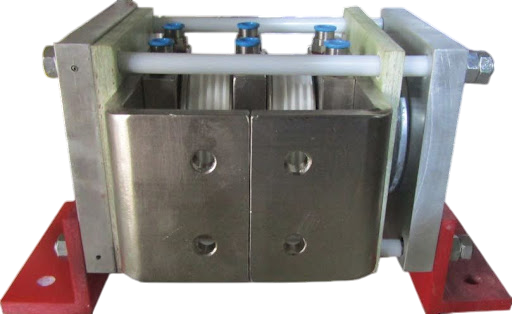

Thyristor Switch Modules are engineered to

overcome the limitations of conventional PFC systems. These modules utilize advanced thyristor

technology to connect or disconnect capacitor banks at the precise zero-crossing point of

voltage or current. This ensures seamless operation without the drawbacks of mechanical

contactors.