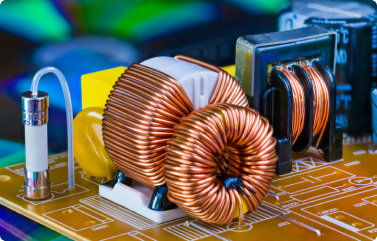

In high-frequency converters, such as those found in Power Factor Correction (PFC) stages, inductors again take center stage. Here, the interaction between the inductor and the capacitor results in a high-frequency energy exchange. The current flowing through the inductor in this scenario is primarily composed of mains frequency harmonics, coupled with a ripple current that corresponds to the operational frequency of the PFC stage. Additionally, inductors are integral to non-isolated high-frequency conversion topologies, such as Buck, Boost, and Buck-Boost converters. In these configurations, the current waveforms vary significantly based on the conduction mode, whether continuous or discontinuous, demonstrating the versatility and importance of inductors in modern power electronics.

Tap for enquiry