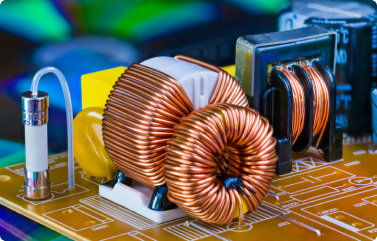

Unmatched Magnetic Characteristics

One of the most significant advantages of iron powder cores is their high magnetic flux density, reaching an impressive 14,000 Gauss (Gs). This characteristic ensures that the cores do not saturate under high magnetic fields, making them ideal for applications requiring consistent performance under varying conditions. Additionally, these cores exhibit excellent DC superimposed characteristics, allowing them to handle direct current (DC) in conjunction with alternating current (AC) without compromising efficiency. This capability makes them a preferred choice in power electronics, transformers, inductors, and various types of magnetic circuits.

Tap for enquiry