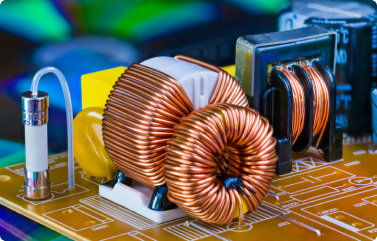

In industrial applications, the need for specific electrical data, efficiency, safety standards, and mechanical dimensions often makes standard transformers unsuitable. This diverse reality drives the continuous development and optimization of switching transformers to meet customer specifications while leveraging advanced technology.

The production of high-frequency components demands stable construction and uniform quality across all batches. Achieving this consistency requires a high level of automation throughout the manufacturing process, from winding and assembly to vacuum casting and final inspection.

Vacuum Casting Process: Developed meticulously over the years, this process ensures very high working voltage levels with minimal distances between windings.

Automation and Inspection: High levels of automation ensure consistent quality, while 100% final inspection phases and in-process checks guarantee product reliability.

Skilled Technical Staff: The expertise and professional know-how of technical staff and workers continuously enhance the technological capabilities of the company.

High-frequency transformers are fundamental to the efficient operation of modern power conversion systems. By transforming voltage and current levels while maintaining galvanic isolation, these transformers ensure safety, efficiency, and performance. Through dedicated customization, advanced production techniques, and stringent quality assurance, we deliver high-quality, reliable transformers tailored to meet the diverse needs of various applications.

Whether you need a standard transformer or a custom solution, we are here to provide the best possible products to enhance your systems. Contact us today to place an enquiry and discover how our high-frequency transformers can meet your specific requirements