Renewable Energy

IGBT stacks play a vital role in renewable energy applications,

particularly in wind and solar power systems. They are used in inverters and

converters to efficiently manage the conversion of DC power generated by solar

panels or wind turbines into AC power suitable for grid integration or local

consumption. The high efficiency and reliability of IGBT stacks make them

indispensable in maximizing energy output and ensuring stable power supply from

renewable sources.

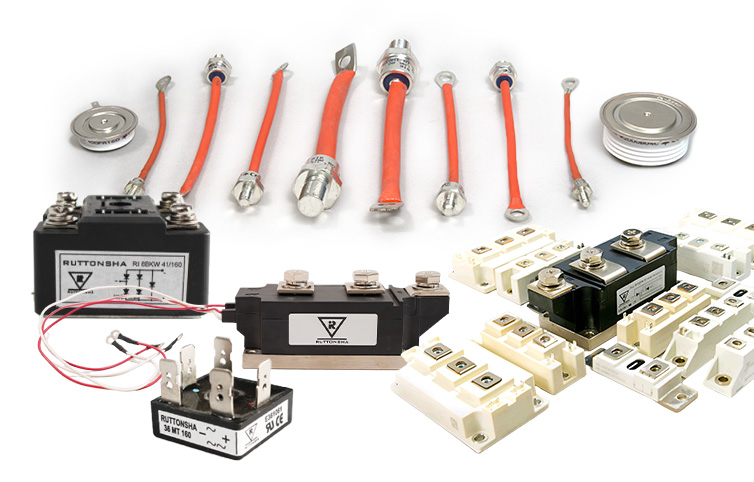

Industrial Automation

In industrial automation, IGBT stacks are used in motor drives and

control systems to regulate the speed and torque of electric motors. Their

ability to handle high currents and voltages, coupled with precise control

capabilities, makes them ideal for applications such as conveyor systems,

robotic arms, and CNC machines. The robust performance of IGBT stacks ensures

smooth and efficient operation of automated processes, enhancing productivity

and reducing downtime.

Transportation

The transportation sector, particularly in electric and hybrid

vehicles, relies on IGBT stacks for efficient power management. These stacks are

used in the powertrain of electric vehicles (EVs) to control the flow of

electricity between the battery and the electric motor. The high efficiency and

rapid switching capabilities of IGBT stacks contribute to the overall

performance and range of EVs, making them a critical component in the push

towards sustainable transportation solutions.

Power Distribution

IGBT stacks are also used in power distribution systems for

voltage regulation and power factor correction. Their ability to handle high

power levels and provide efficient switching makes them suitable for use in

substations and distribution networks. By ensuring stable and reliable power

delivery, IGBT stacks help maintain the quality and integrity of electrical

supply in both urban and rural areas.

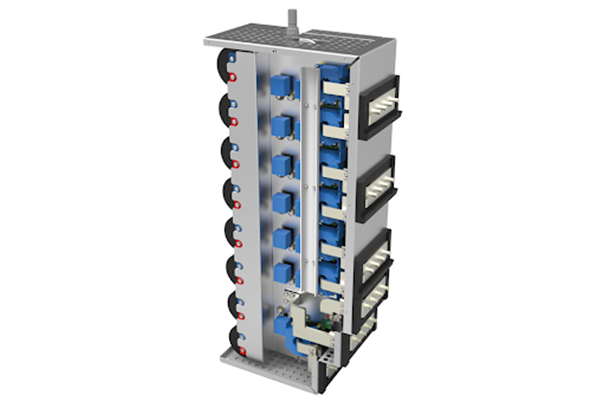

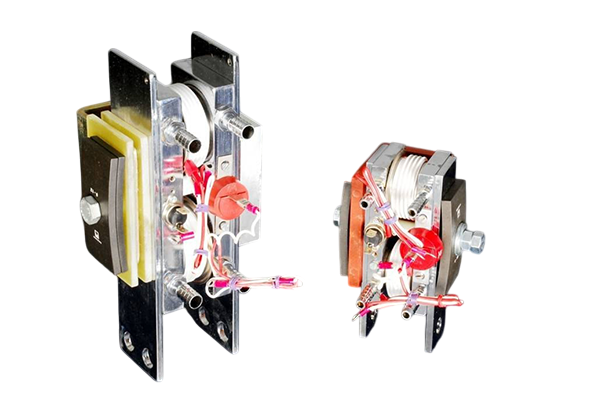

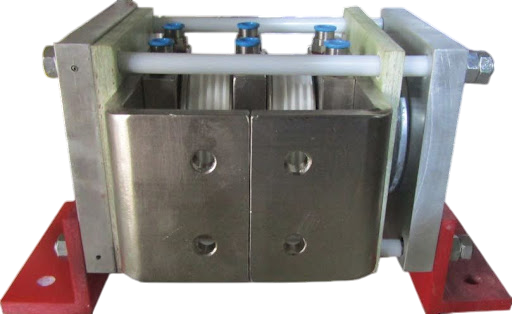

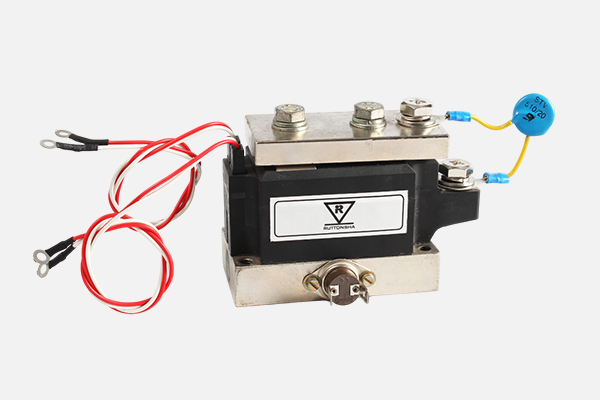

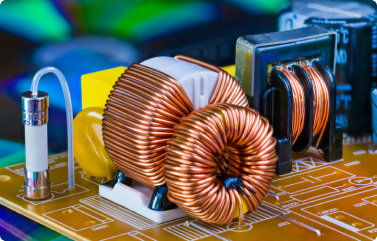

IGBT stacks are integral to modern power electronics, offering

unmatched efficiency, reliability, and versatility in a wide range of

applications. Whether in renewable energy, industrial automation,

transportation, or power distribution, these stacks provide the performance and

robustness needed for efficient power management. The advanced cooling

mechanisms, flexible mounting options, and durable construction of IGBT stacks

make them a preferred choice for engineers and designers looking to optimize

power systems. With continuous advancements in technology, IGBT stacks will

continue to play a pivotal role in the evolution of power electronics, driving

innovation and sustainability in various industries.