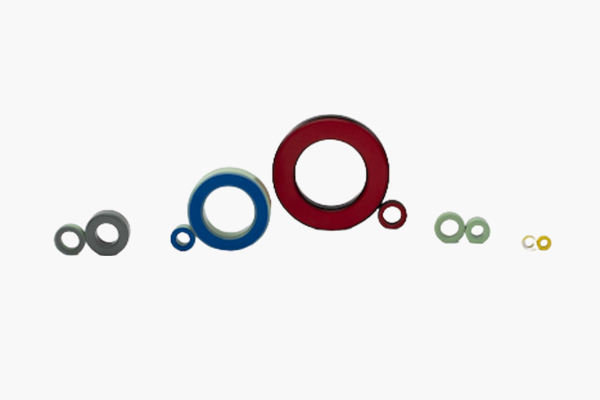

Amorphous cores find wide-ranging

applications across various industries, particularly in sectors where energy

efficiency, compact design, and reduced operational costs are critical. Here are

some of the most prominent applications:

Energy-efficient

Transformers: : Amorphous core transformers are renowned for their

energy-saving capabilities. With significantly lower core losses compared to

traditional transformers, they reduce energy wastage, leading to cost savings

and a lower environmental footprint. These transformers are particularly

beneficial in applications such as power distribution, where minimizing energy

losses is crucial for operational efficiency.

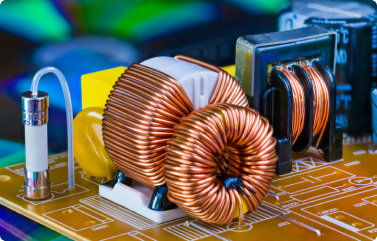

Inductors and

Chokes: In power electronics, inductors play a pivotal role in

filtering, energy storage, and power conversion. Amorphous core inductors, with

their low losses and high magnetic permeability, ensure improved performance in

DC-DC converters, inverters, and other power management systems. They are also

used in choke applications to reduce noise and EMI (electromagnetic

interference), making them essential components in modern electronic devices.

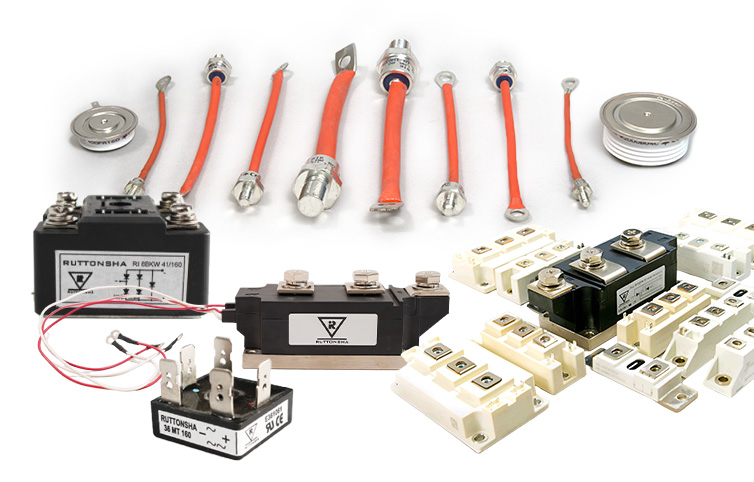

Power Electronics:

The growing demand for renewable energy sources and electric vehicles has

accelerated the adoption of amorphous cores in power electronics. Their ability

to handle high frequencies and temperatures, combined with their low core

losses, makes them an excellent choice for high-frequency transformers and other

components in inverters, converters, and motor drives used in renewable energy

systems and electric vehicles.

Uninterruptible Power

Supplies (UPS): Amorphous cores are widely used in UPS systems, where

efficiency and reliability are critical. These systems must maintain continuous

power flow during outages, and amorphous core transformers ensure minimal energy

loss while delivering uninterrupted power to critical loads.

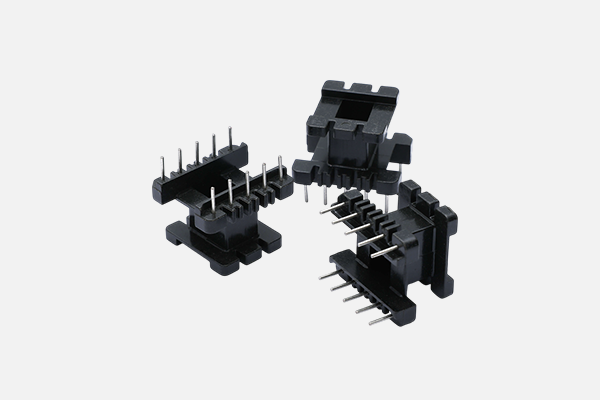

High-frequency

Applications: In high-frequency applications such as telecommunications,

aerospace, and industrial automation, amorphous cores are favored due to their

ability to maintain performance at elevated frequencies without significant

losses. They are often used in high-frequency transformers, sensors, and

filters, where precision and efficiency are paramount.