Custom Solutions:

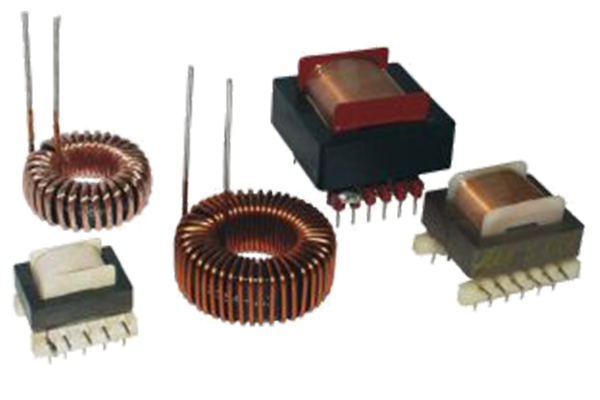

Given the diverse needs of various applications, standard CTs may not always

meet specific requirements. Our company specializes in developing customized

current transformers that align perfectly with client specifications. This

involves tailoring aspects such as core material, winding configuration, and

housing design to achieve the desired performance characteristics.

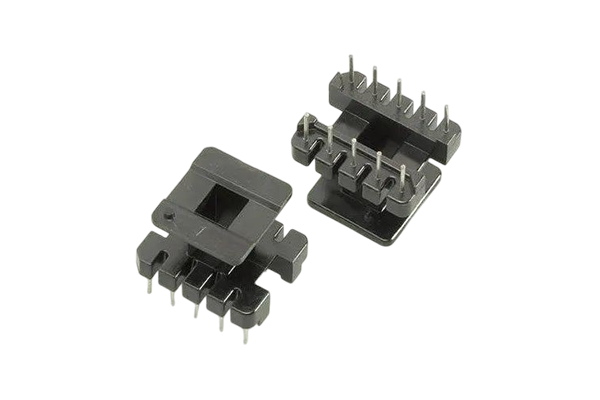

Automation and Quality

Assurance: The production of high-quality CTs requires advanced

automation and rigorous quality control. From the winding process to final

assembly and testing, each step is meticulously monitored to ensure consistency

and reliability. Vacuum casting and automated inspection processes further

enhance the durability and performance of our transformers.

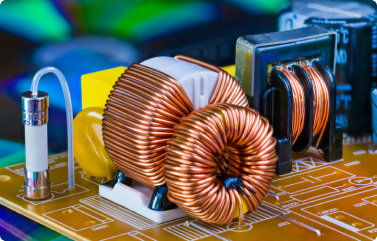

Innovation and

Technology: Our commitment to continuous improvement drives our

innovation in CT technology. By integrating cutting-edge materials and

manufacturing techniques, we ensure that our transformers meet the highest

standards of efficiency and accuracy. Our technical staff's expertise and

dedication play a crucial role in pushing the technological boundaries of our

products.

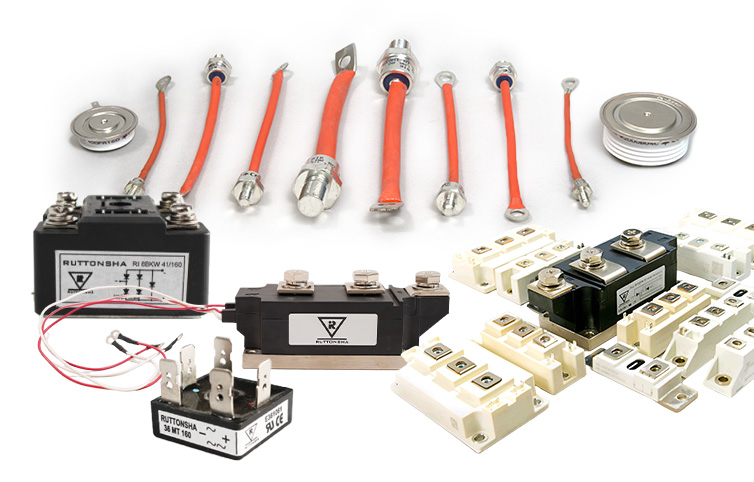

Current transformers are indispensable components in modern electrical

systems, offering precise current measurement, isolation, and safety. With

various types available, including mains frequency, measurement-specific, and

high-frequency CTs, it is crucial to select the appropriate transformer for each

application. Our advanced development and production capabilities ensure that we

provide high-quality, customized solutions that meet the specific needs of our

clients.

For more information or to make an enquiry, contact us today. We are here to

help you find the ideal current transformer for your needs, ensuring exceptional

performance and reliability. Optimize your electrical systems with our

cutting-edge solutions.