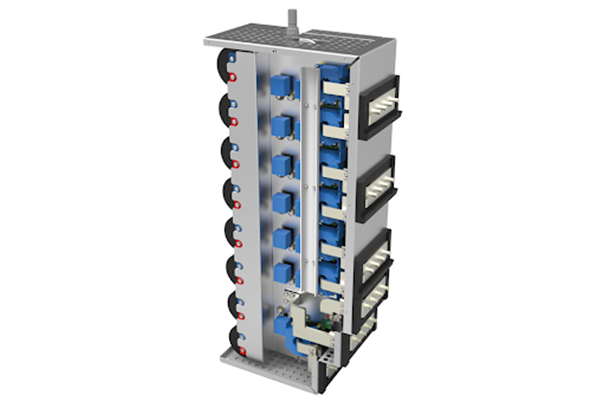

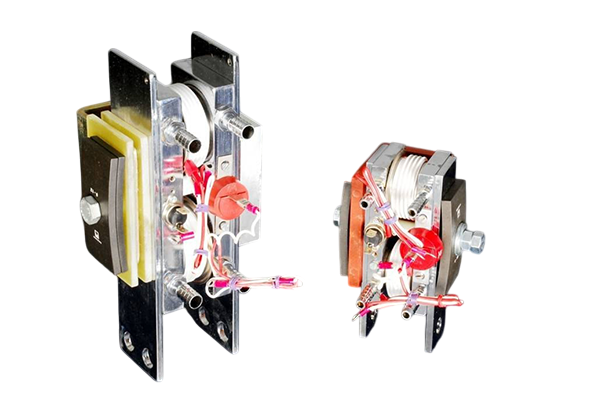

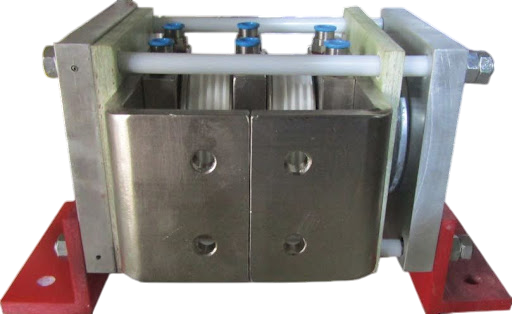

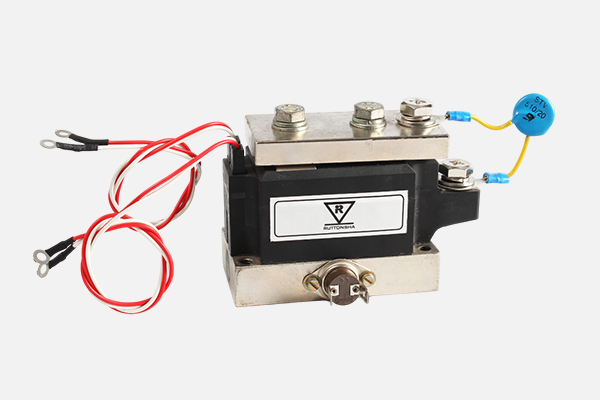

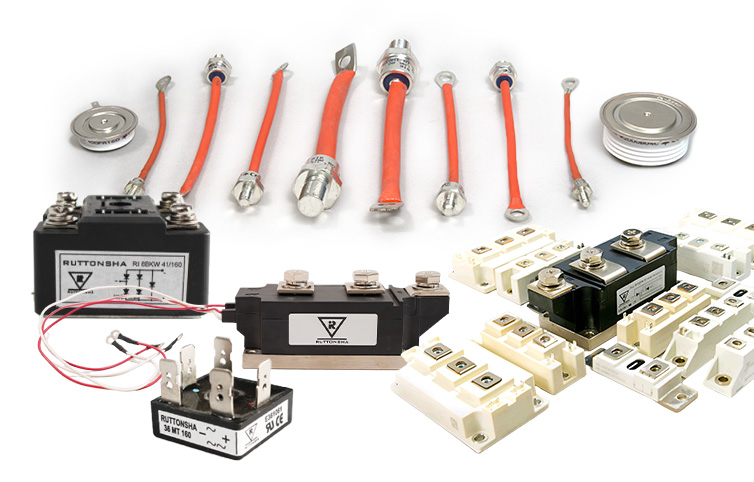

Our thyristor stacks are engineered to handle varying voltage and current requirements with precision. The B6U 2Q configuration is optimized for applications requiring high reliability and efficiency in power control.

Thyristor Stacks (B6U) offer versatility and efficiency in power control. Various models are available to cater to different voltage and current requirements. For example, the 600 PE 16 model supports a 450 V input, delivering a continuous current of 800A and accommodating overloads of 560A for 1 minute and 440A for 2 hours. Advanced models like the 3500 PQ 22 can handle inputs up to 700 V and deliver continuous currents of 3550A, with short-term overload capacities reaching 2375A for 1 minute and 2225A for 2 hours, all within a compact stack size of 750×500×750 mm. These Thyristor Stacks are designed with multiple cooling fans and suitable enclosures to maintain performance and longevity under varying operational conditions.

Our thyristor stacks are designed to provide maximum efficiency, with each class tailored to specific application requirements, ensuring optimal performance across a wide range of industrial uses.

Tap for enquiry