Enhanced Efficiency

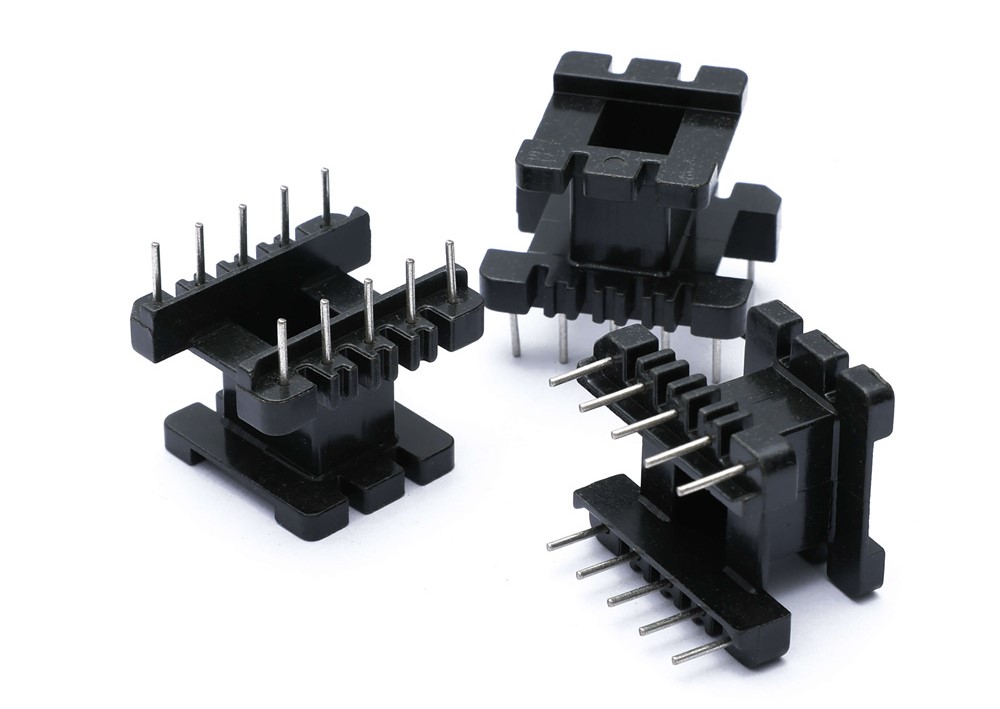

Bobbins contribute significantly to the

efficiency of winding processes by providing a stable and organized structure.

This reduces material wastage and ensures consistent performance in the final

product. The use of bobbins in automated winding processes enhances productivity

and reduces the likelihood of errors, leading to higher throughput and lower

production costs.

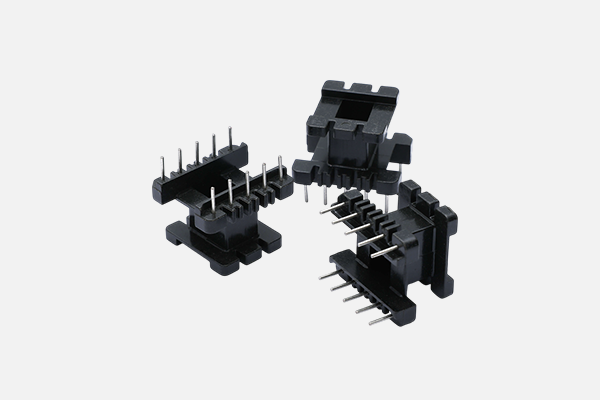

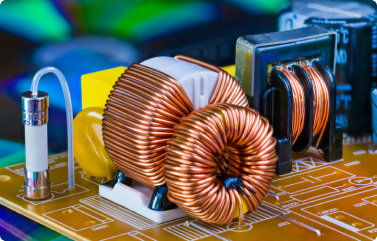

Superior Product Quality

By maintaining precise tension and

arrangement of winding materials, bobbins help produce high-quality coils and

threads. This is particularly important in applications where even minor

inconsistencies can lead to significant performance issues. The uniform winding

on bobbins ensures that the final products meet stringent quality standards and

perform reliably in their intended applications.

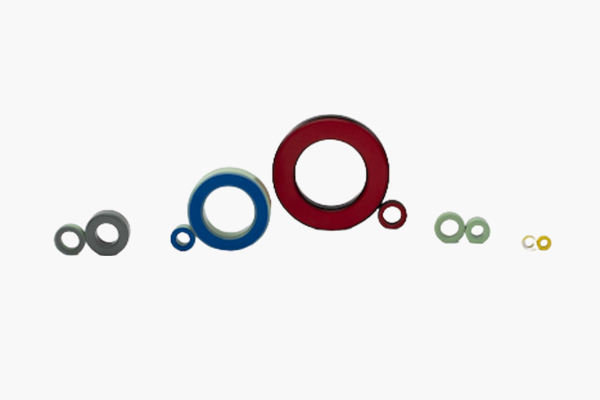

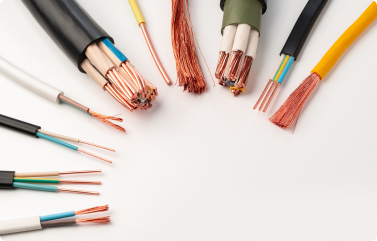

Versatility

Bobbins are versatile components that can

be adapted for a wide range of applications. Their flexibility in accommodating

different materials and designs makes them suitable for diverse industries, from

heavy-duty industrial machinery to delicate medical devices. Custom-designed

bobbins can meet the specific needs of various applications, providing a

tailored solution for each unique requirement.

Cost-Effectiveness

Using bobbins can lead to significant cost

savings by minimizing material waste and improving manufacturing efficiency.

Their durability and reusability further contribute to long-term cost benefits.

The ability to produce high-quality components consistently with bobbins reduces

the need for rework and repairs, leading to lower overall production costs.

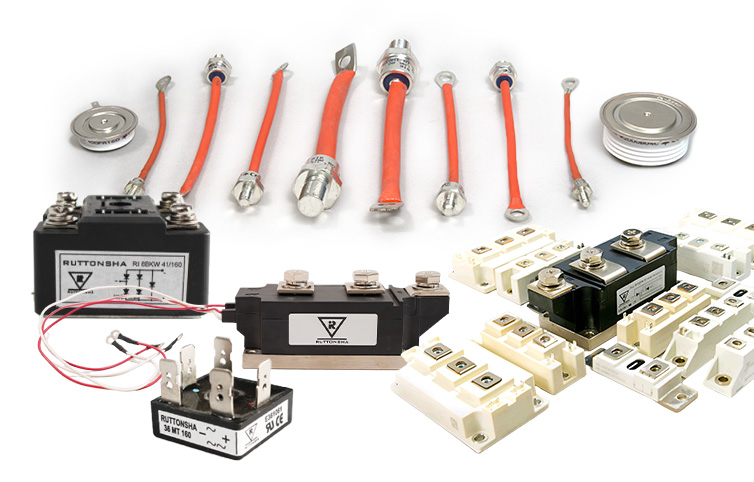

Bobbins are foundational elements that

underpin the efficiency and precision of winding processes across various

industries. Their ability to organize and maintain the tension of winding

materials is crucial for producing high-quality products and ensuring the smooth

operation of manufacturing systems. Whether in electrical engineering, textile

production, medical devices, or automotive components, bobbins are indispensable

tools that drive the success and reliability of numerous applications.

Embrace the power of well-crafted bobbins

to elevate your manufacturing processes and achieve exceptional results. For

more information or to place an enquiry, reach out today and discover how

customized bobbin solutions can optimize your specific applications, ensuring

superior performance and reliability.