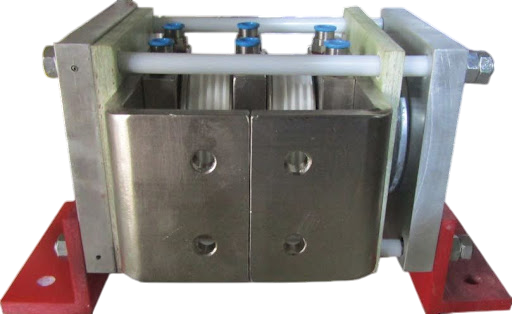

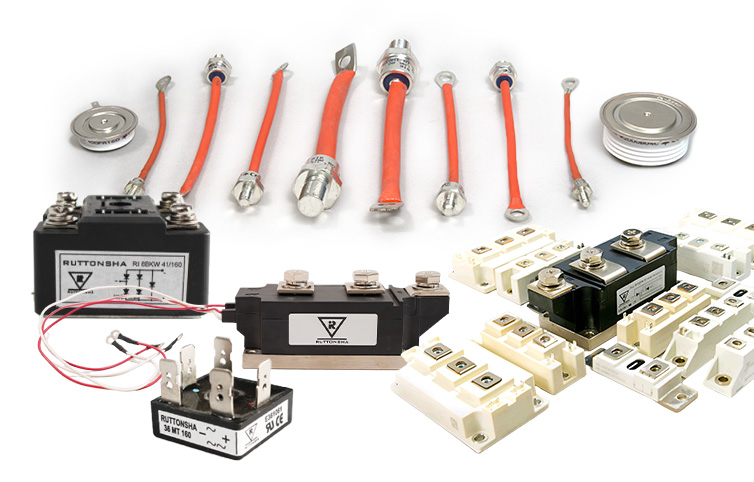

Stable DC Output:

The primary function of welding rectifier stacks is to provide a stable DC

output, which is essential for achieving precise and high-quality welds. The

consistent output ensures minimal fluctuation, reducing the risk of defects in

the weld.

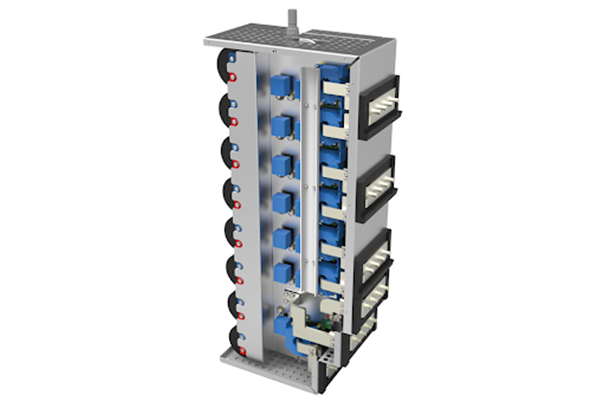

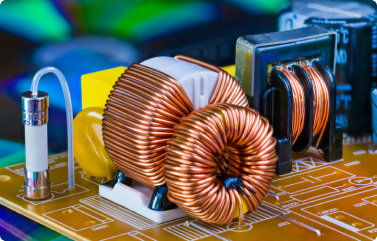

Advanced Cooling

Mechanism: Equipped with aluminum heatsinks, these rectifier stacks are

designed for efficient heat dissipation. The enhanced cooling mechanism ensures

that the components remain within safe operating temperatures, thereby extending

their lifespan and maintaining performance under heavy load conditions.

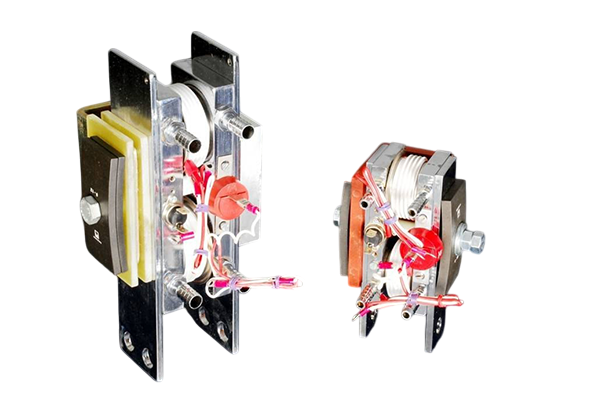

Auto Diodes and

Ceramic Bushes: The integration of auto diodes and ceramic bushes

enhances the operational efficiency and reliability of the rectifier stacks.

Auto diodes ensure quick and efficient rectification, while ceramic bushes

provide excellent insulation and durability.

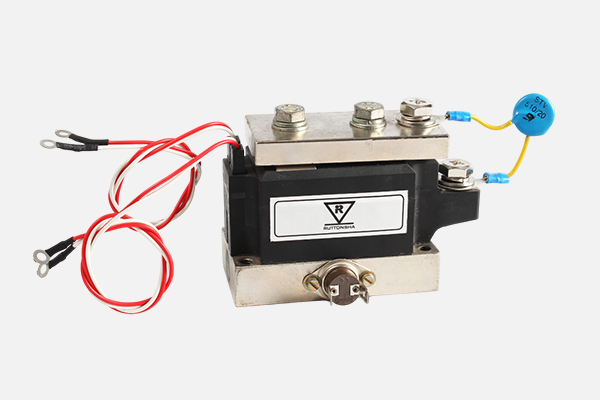

High Input Current

Capacity: Our welding rectifier stacks come in various models with

different input current capacities to meet diverse welding needs. The S240 model

supports an input current of 240 A, the S400 model supports 400 A, the S600

model supports 600 A, and the S800 model supports 800 A. This range ensures that

there is a suitable model for both light and heavy-duty welding applications.