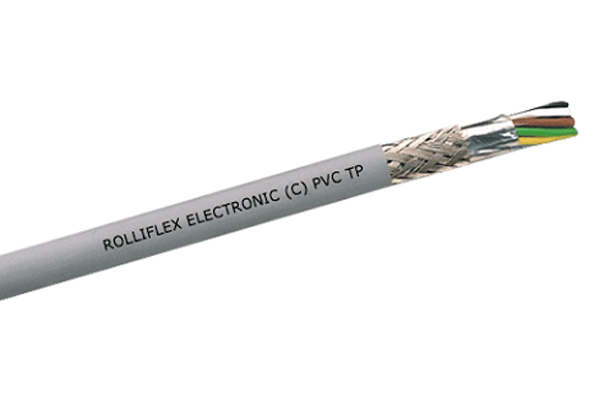

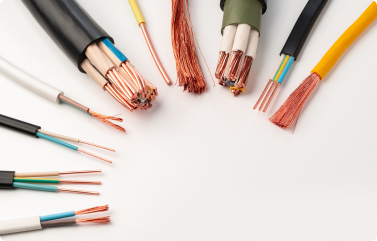

High Temperature Cables

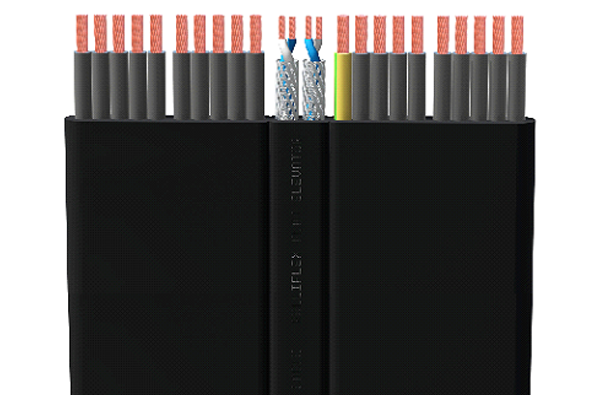

When it comes to high-temperature applications, the right cables and wires are crucial for safety, performance, and longevity. Rolliflex High Temperature Cables stand out due to their exceptional temperature range, superior quality, and outstanding chemical resistance. Engineered with advanced insulating materials such as FEP, PFA, PTFE, ETFE, and PEEK, these cables are designed to meet the most demanding requirements. Let's delve into the features, specifications, and benefits of Rolliflex High Temperature Cables.

Tap for enquiry