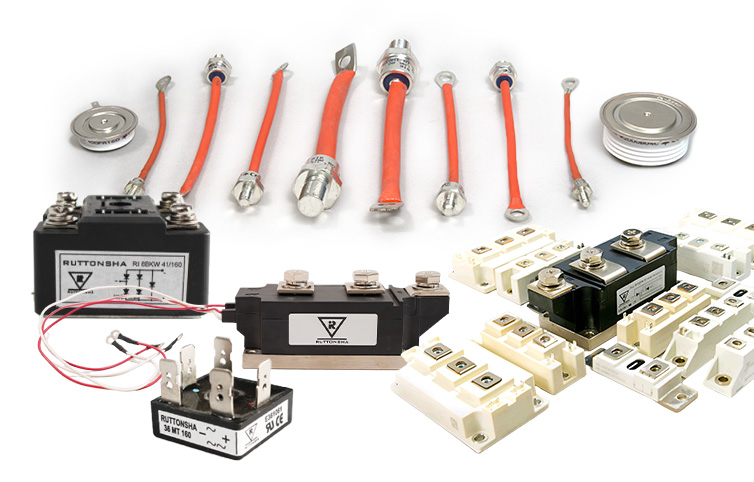

Thermal Insulator Pads offer an advanced solution to these challenges by providing a high-performance thermal interface that enhances heat dissipation while maintaining electrical insulation. Unlike traditional thermal greases, mica sheets, and ceramic insulators, these pads are clean, easy to handle, and highly efficient in conducting heat away from power semiconductors.

Thermal greases, though widely used, can be messy and difficult to apply uniformly. They also tend to dry out over time, leading to inconsistent thermal conductivity and reduced efficiency. Similarly, mica and ceramic insulators, while offering electrical insulation, come with drawbacks such as high thermal resistance, brittleness, and mechanical fragility. These limitations make them less effective in applications requiring consistent, long-term thermal performance.

Tap for enquiry