Thermal Conductivity

The primary function of a heat sink compound is to provide superior thermal conductivity. High-quality compounds are engineered to have low thermal resistance, enabling them to efficiently transfer heat from the component to the heat sink.

Viscosity and Consistency

Heat sink compounds must possess the right viscosity to spread evenly and thinly without flowing out of place. This ensures optimal contact between surfaces and maximizes thermal transfer.

Stability and Longevity

A good heat sink compound maintains its consistency and performance over time, even under varying temperatures and environmental conditions. It should resist drying out, cracking, or becoming less effective.

Electrically Non-Conductive

Many heat sink compounds are designed to be electrically insulating, preventing any risk of short circuits or electrical interference between components.

Heat sink compounds find application in a wide range of industries and devices, playing a pivotal role in maintaining thermal efficiency and reliability:

Computing Devices

In computers, heat sink compounds are indispensable for cooling CPUs, GPUs, and other high-performance components. They ensure that these critical parts remain within safe operating temperatures, preventing thermal throttling and extending their lifespan.

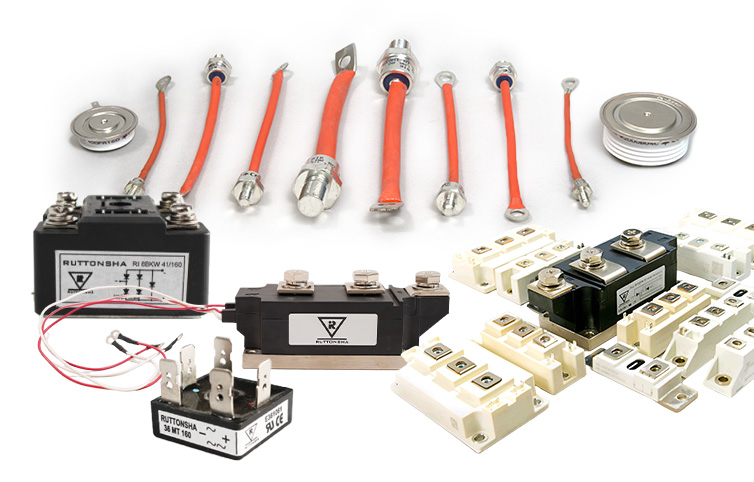

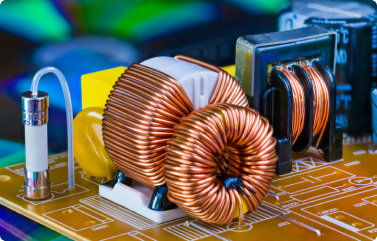

Power Electronics

Power transistors, voltage regulators, and other power electronic devices generate significant heat. Heat sink compounds help dissipate this heat effectively, ensuring stable performance and preventing overheating in power supplies, inverters, and motor drives.

LED Lighting

LEDs are known for their efficiency, but they still generate heat. Applying heat sink compound between the LED and its heat sink ensures optimal heat dissipation, maintaining brightness and prolonging the life of the LEDs.

Automotive Electronics

In vehicles, electronic control units (ECUs), sensors, and power modules rely on heat sink compounds to manage heat. This is critical for the reliable operation of automotive electronics in varying temperature conditions.

Enhanced Performance

By maximizing thermal conductivity, heat sink compounds ensure that electronic components operate at their best, maintaining performance levels even under heavy loads.

Increased Longevity

Efficient heat dissipation prevents overheating, which can degrade components over time. Heat sink compounds contribute to extending the lifespan of electronic devices by maintaining safe operating temperatures.

Improved Reliability

Stable thermal management ensures that devices function reliably without unexpected shutdowns or thermal-induced failures. This is particularly important in mission-critical applications such as aerospace, medical devices, and telecommunications.

Cost-Effective Solution

Heat sink compounds are a cost-effective way to improve thermal performance without the need for more expensive cooling solutions. They provide a simple yet highly effective method for enhancing heat dissipation

Choosing the Right Heat Sink Compound

Selecting the appropriate heat sink compound involves considering factors such as thermal conductivity, viscosity, and compatibility with the application. Different formulations are available to suit various needs, from high-performance computing to industrial applications.

In the fast-paced world of electronics, efficient thermal management is not just a preference—it's a necessity. Heat sink compounds, with their ability to bridge the thermal gap and enhance heat transfer, are indispensable tools in achieving this goal. Whether in computing, power electronics, LED lighting, or automotive applications, these compounds ensure that your components perform optimally, last longer, and operate reliably. For more information or to place an inquiry, connect with us today. Discover how our advanced heat sink compounds can elevate your electronic systems to new heights of thermal efficiency and reliability.